We are a certified and innovative family operated business with 50 years of experience in Toolmaking, Jig and Fixture Construction, Precision Mechanics and Machine Engineering.

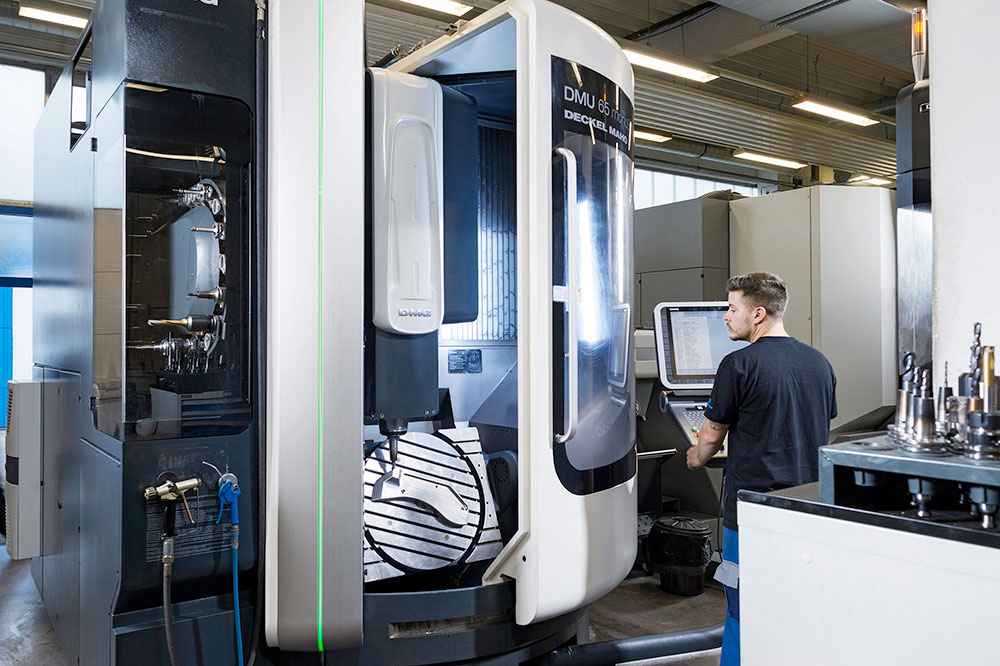

As a full-service contract manufacturer, we specialize in precision turning and lathing, milling, drilling, flat grinding and erosion, and we guide and support our customers from their initial concept to the finished product.

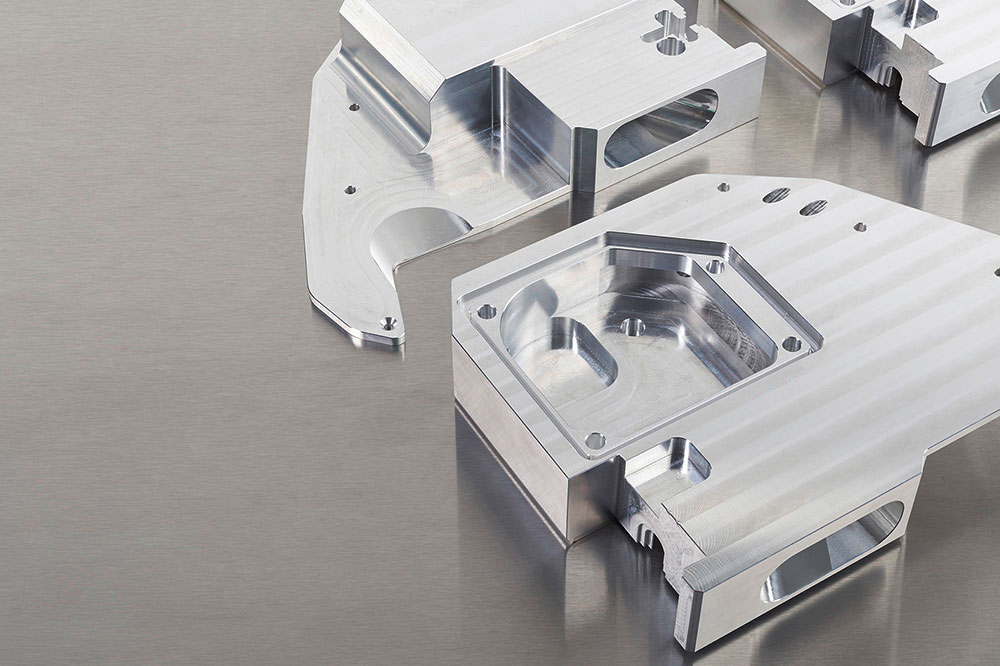

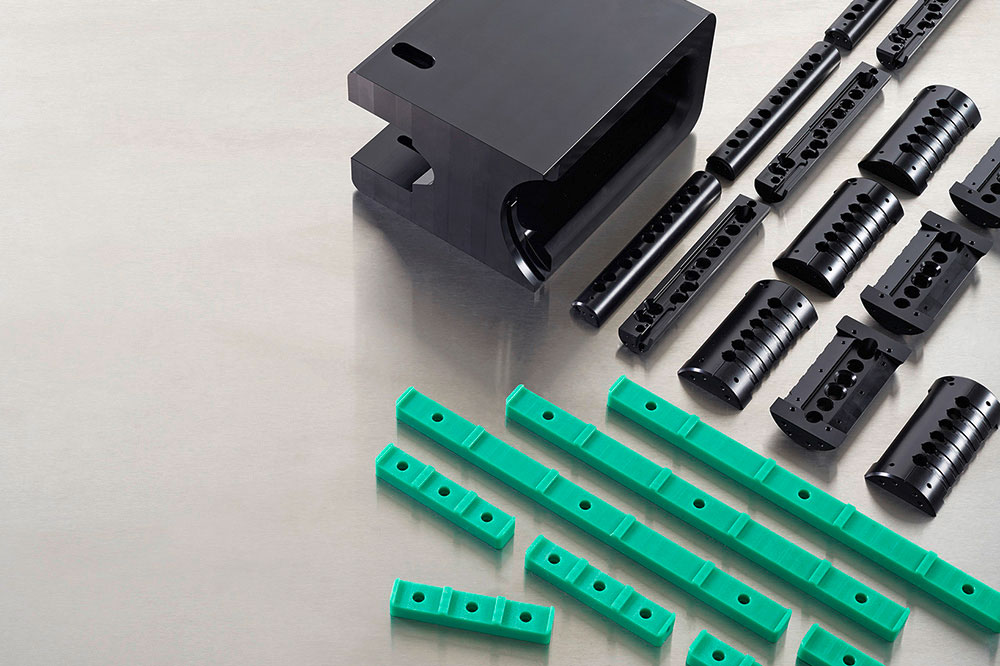

We manufacture sophisticated parts and components for our customers in the fields of gas turbine manufacturing, nuclear reactor engineering, aerospace technology, 3D printer technology, and medical and sensor technology.

Our highest quality standards and our flexibility assure that we can successfully meet the most complex customer requirements.

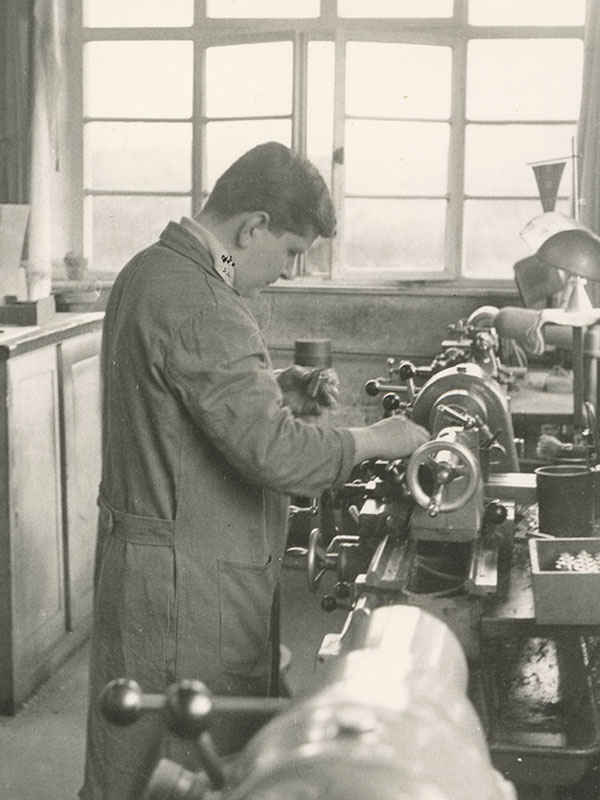

1967 Ottmar Buchberger establishes his firm in a garage in Nuremberg, where, using a line shaft driven lathe and drilling machine, he produces small parts for the firm Grundig AG. 1978 After a short move to Burgfarrnbach the business relocates to Tuchenbach, where the firm is still located today.

1988 Construction of a new manufacturing facility having 2500m² production space.

2002 Expansion of the facility by approx. 1000m² to increase turning and lathe machining capacity.

2007 Acquisition of a 3000m² warehouse.

Conversion of a 1200m² production building for manufacture of small parts and components.

2012 Management is transferred to the second Buchberger generation. Bernd, Bruno und Michael Buchberger assume the responsibility of executing company philosophy and maintaining the highest quality standards

2017 In commemoration of its 50th business anniversary, Ottmar Buchberger GmbH presents its new logo and announces the expansion of its manufacturing and administrative facilities at its Tuchenbach location.

We currently employ approximately 100 qualified employees, who dedicate themselves, within our manufacturing, quality management and administrative processes, to the on-schedule supply of sophisticated parts and components to our satisfied customers active in the gas turbine manufacturing, nuclear reactor engineering, aerospace technology, 3D printer technology, and medical and sensor technology industries.

- CNC Milling Machines

- Conventional Milling Machines

- CNC Turning Machines

- Conventional Turning Machines

- EDM Machines

- Grinding Machines

- Measurement Technology

- Download

CNC Milling Machines

| Brand and Model | Traverse Range | Additional Information | |||

|---|---|---|---|---|---|

| x | y | z | |||

| 1 | Waldrich Taurus 30 | 6000 | 4000 | 1500 | passage weight 3000, passage height 3000, table size 2500x5000, 5 exchange milling heads incl. universal swiveling head, round table Ø2200 |

| 1 | Reiden Rx12 | 1300 | 1450 | 1000 | 5 Axis A/C, execution as turning -milling centre, table diameter 1200, star shaped grooves, |

| 1 | Zayer Xios G1500 | 2500 | 1500 | 1600 | 6 Axes Rotary Table 1500 x 1500 |

| 1 | Zayer Kairos | 10000 | 1500 | 3000 | 7 Axes Rotary Table 2500 x 2500 |

| 1 | Wotan Rapid 1 | 2000 | 1600 | 1250 / 600 | 4 Axes Rotary Table 1600 x 1250 |

| 1 | Reiden BFR24 | 4000 | 1200 | 1000 | 5 Axes B/C B360º / Ø2000 |

| 1 | Reiden BF5-L | 4000 | 1000 | 1500 | 4 Axes B B±90º / Hirth2,5º |

| 2 | Reiden BF5-H | 3000 | 1000 | 1500 | 5 Axes B/C B±90º manual / Ø1200 |

| 1 | Reiden BF4 | 2400 | 1000 | 800 | 4 Axes B B±90º manual |

| 1 | DMG DMF 250 | 2500 | 920 | 820 | 5 Axes B/C B±100º / Ø800 |

| 1 | DMG DMF 180 | 1800 | 700 | 700 | 5 Axes B/C B±100º / Ø750 |

| 1 | DMG DMU 65 | 735 | 650 | 560 | 5 Axes A/C A±120º / Ø650 |

| 1 | DMG DMU 75 | 735 | 650 | 560 | 5 Axes A/C A±120º / Ø650 |

| 1 | DMG DMU 105 | 1135 | 1050 | 750 | 5 Axes A/C A±120º / Ø1050 |

| 1 | DMG DMU 100 T | 1190 | 710 | 710 | 5 Axes B/C B+12º/-94º / Ø800 |

| 1 | DMG DMU 100 T2 | 1230 | 710 | 710 | 5 Axes B/C B+30/-120º / Ø800 |

| 1 | DMG DMU 125P | 1250 | 880 | 800 | 5 Axes B/C B+180° / Ø1250 |

| 1 | Doosan Mynx 6500/50 | 1270 | 670 | 625 | |

| 2 | MTRent MTCUT V110 | 1100 | 600 | 600 | Optional 5 Axes A/C A±90° / Ø350 |

| 2 | MTRent MTCUT V110 T | 1100 | 600 | 600 | Optional 5 Axes A/C A±90° / Ø350 |

| 6 | MTRent MTCUT V110 12 TH | 1100 | 600 | 600 | |

| 3 | MTRent MTCUT UE110-5A | 1100 | 600 | 600 | |

| 1 | Wemas VZ 1200 Master | 1200 | 750 | 650 | |

| 1 | Deckel FP42NC | 1200 | 350 | 300 | |

| 1 | Deckel FP4NC | 560 | 500 | 450 | 4 Axes C Rotary Table Ø500 |

| 1 | Deckel FP7NC | 1000 | 700 | 500 | 4 Axes C Rotary Table 900 x 800 |

Conventional Milling Machines

| Brand and Model | Traverse Range | Additional Information | |||

|---|---|---|---|---|---|

| x | y | z | |||

| 4 | Deckel FP1 | 300 | 150 | 340 | |

| 1 | Deckel FP2 | 400 | 200 | 400 | |

| 1 | Deckel FP3 | 500 | 300 | 380 | |

| 1 | Deckel FP3LV | 800 | 300 | 400 | |

CNC Turning Machines

| Brand and Model | Traverse Range | Additional Information | ||

|---|---|---|---|---|

| Turning Diameter | Turning Length | |||

| 1 | Waldrich ValuTurn 3000AS | Ø2500 (DG Ø3100) | 3.000 | Part weight up to 25 tons |

| 1 | Safop 60/2500-CNC-Leonard | Ø2500 | 6000 | |

| 2 | Safop L-60/2500-CNC | Ø2500 | 1200 | |

| 1 | Wohlenberg PT1S-1800 IV | Ø1800 | 1500 | |

| 1 | IMT VBM 25.32 | Ø2500 (Ø3200) | 2000 | Vertical Lathe |

| 1 | Weiler E110 | Ø1100 | 3000 | Rod passage Ø128 |

| 1 | Weiler E40 | Ø400 | 1000 | |

| 1 | Gildemeister NEF 400 | Ø210 | 650 | Rod passage Ø60 |

| 1 | Spinner TC800 77MC | Ø310 | 800 | Rod passage Ø70 |

Conventional Turning Machines

| Brand and Model | Traverse Range | Additional Information | ||

|---|---|---|---|---|

| Turning Diameter | Turning Length | |||

| 1 | PBR T-700C | Ø1400 (Ø1700) | 4000 | |

| 1 | Weiler DA260 | Ø500 | 1500 | |

| 1 | Weiler DA260 | Ø500 | 2000 | |

| 1 | Weiler Condor81 | Ø200 | 500 | |

| 1 | Weiler Praktikant | Ø200 | 500 | |

| 3 | Weiler Primus | Ø240 | 500 | |

EDM Machines

| Brand and Model | Traverse Range | Additional Information | |||

|---|---|---|---|---|---|

| x | y | z | |||

| 1 | CDM-Rovella BF 1200 Zenit | 1200 | 600 | 500 | |

| 1 | CDM-Rovella VS 1200 HS Zenit+ | 1200 | 600 | 500 | |

| 1 | Sodick AQ15L | 900 | 1800 | 600 | |

Grinding Machines

| Brand and Model | Traverse Range | Additional Information | |||

|---|---|---|---|---|---|

| x | y | z | |||

| 1 | Ziersch ZT 48 | 400 | 800 | 400 | |

| 1 | Ziersch ZT 612 | 600 | 1200 | 400 | |

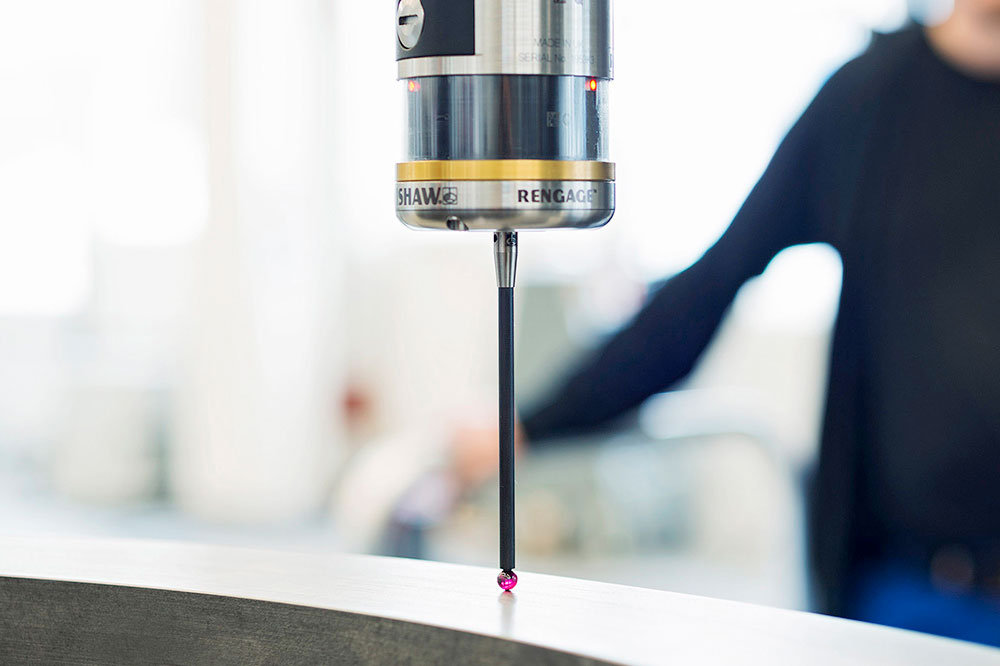

Measurement Technology

| Brand and Model | Traverse Range | Additional Information | |||

|---|---|---|---|---|---|

| x | y | z | |||

| 1 | Mitutoyo Crysta-Appex 7106 | 700 | 1000 | 600 | CMM |

| 1 | Mitutoyo Crysta-Appex 776 | 700 | 700 | 600 | CMM |

| 1 | Mitutoyo Quick Vision Active 404 Touch probe | 400 | 400 | 200 | |